know-how

harvest

The harvest takes place at the beginning of autumn, most often the last week of September when the grapes are perfectly ripe. We control as many elements as possible to harvest the grapes in their best condition. Systematically, we harvest early in the morning, at 4am, when the temperatures are cooler, to avoid unwanted fermentation. The grapes are poured into small containers to prevent them from being crushed and releasing too much juice. They are transported as quickly as possible to the wine cellar to avoid uncontrolled fermentation or maceration. Our scrupulous selection of grapes of Ugni Blanc and Baco are harvested in higher yields in order to achieve their full aromatic potential. These grape varieties require higher yields in order to obtain distillation wines that are rich in total acidity, and low in alcohol and volatile acidity.

distillation

Distillation is carried out during the winter, no later than March 31 of the year following the harvest. We like to distill when the outside temperatures are at the lowest to maintain the wine at 10-12℃ (50-54℉). The wine is distilled at the property with the help of a trusted traveling distiller who we have used for years. Armagnac is obtained with a very specific alembic: the Armagnac continuous still. This is a pure copper device, which was consecrated by a patent filed in 1818 by Sieur Tuillière, under the reign of King Louis XVIII, and adapted, modified and improved by the distillers of the region. This particular alembic contributes to the uniqueness of Armagnac. When it comes out of the still, the brandy is colorless, and we meticulously control its alcohol content, which varies between 52 and 58% vol. (104-116 proof). At this stage, the Armagnac is still full of vigor and is already of great aromatic richness: very fruity (plum, grape) and often floral (vine or lime blossom). Aging it in French oak will give it additional complexity and softness.

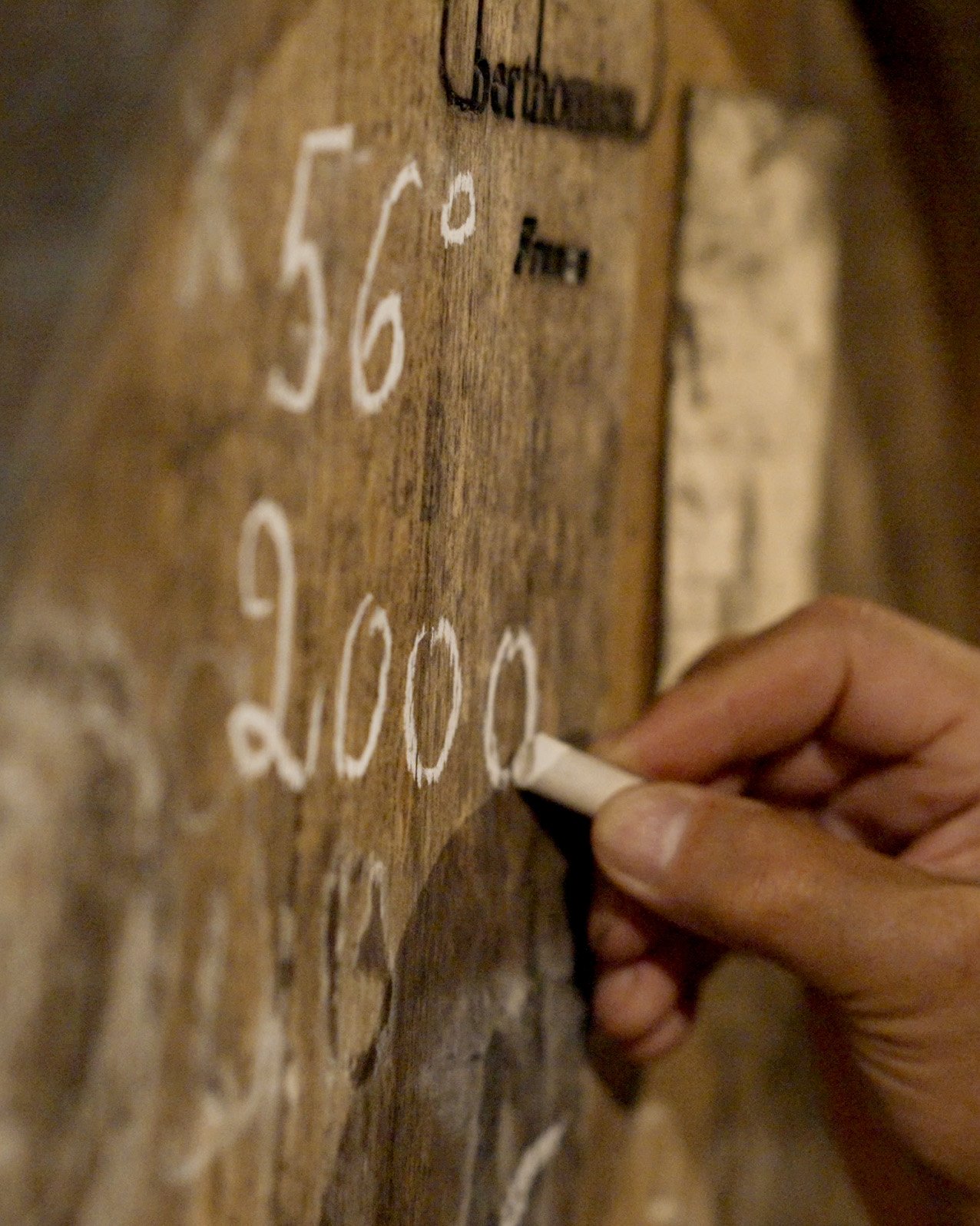

AGING

Our eaux-de-vie are mostly aged in new casks from the Tronçais forest in the center of France for a period of 3 years before being transferred to older barrels which have previously housed other Armagnacs. The timber forest of Tronçais was created in the 17th century by Colbert, Louis XIV’s chief minister, in order to build warships for the royal fleet. It is made up of oaks from the same age, where the density is high. Often these trees can exceed 200 years of age. Their grain tends to be tighter than that of others. These oaks respect the eau-de-vie while giving it finesse, tannins and structure. Their tannins are known to be particularly soft, providing a good length finish in the mouth. Some of our eaux-de-vie are also placed in oak barrels from Gascony, the most traditionally used for the aging of Armagnac. These oaks produce a wide-grain wood, more easily releasing the tannins suited to the power of the brandy.

To create a natural ripening, the staves used for our casks have been exposed to the open air in parks devoid of any pollution for a period of at least 24 months. The staves are pieces of oak split into thin assembled planks to form wooden panels that are used to make barrels. Our cooper (barrel maker) applies a unique steam bending technique during barrel making. The passage of steam plays a final role in the "purification" of the wood, helping to eliminate harsh tannins.

We have two very distinct types of cellars: dry and wet, giving each barrel unique characteristics. The dry cellar evaporates the volume but not the alcohol while in the wet cellar there is more evaporation of alcohol but less evaporation of volume. In terms of aromas, the dry cellar generally offers a more incisive character while the wet cellar makes our Armagnacs rounder and smoother.